Auto builders expect the highest standards of precision in components. A critical aspect is achieving a perfect appearance on concave edges, which can be tough with traditional approaches. Our innovative Precision Dished EndAC Polishing Machine solves this call by presenting an mechanized and meticulous remedy. This device employs customized tooling and a guided polishing method to achieve a glossy surface on dished ends, maintaining optimal productivity and durability of automotive segments.

- The machine’s programmable controls provide for precise tweaks to the polishing criteria, validating homogeneity and replicability.

- Its condensed structure amplifies workspace effectiveness while reducing operator stress.

- Merging with existing manufacturing processes is smooth, enhancing production progressions.

Advanced Tank Polishing Machines for Stainless Steel Fabrication

In the territory of stainless steel production, accomplishing a impeccable and gleaming surface is critical. To achieve this objective, high-efficiency tank polishing machines have come forth as essential instruments. These cutting-edge machines employ cutting-edge technology to smoothly remove surface blemishes and enhance a shiny sheen on stainless steel tanks.

- What's more, high-efficiency tank polishing machines are crafted for optimal performance, including durable construction, strong motors, and creative polishing heads that cut down surface damage.

- Consequently, fabricators can attain exceptional results with minimal effort, simplifying their production methods and supplying high-quality tanks that adhere to the stringent criteria of various domains.

Leading Cylindrical Polishing System for Precision Engineering

The necessity for exceptional surface quality in precision engineering is constantly increasing. To meet these rigorous demands, a revolutionary cylindrical polishing system has been created. This state-of-the-art system employs cutting-edge processes to attain unparalleled surface smoothness. It efficiently removes imperfections and enhances the overall effectiveness of cylindrical segments across a wide range of specialties.

- Pros include increased yield, reduced manufacturing charges, and improved product dependability.

- The system is configured to handle a wide range of materials, including metals, ceramics, and plastics.

- Handlers can easily regulate the polishing controls to reach the desired texture.

This advanced cylindrical polishing system represents a significant leap forward in precision engineering, enabling manufacturers to produce pieces of exceptional worth and operation.

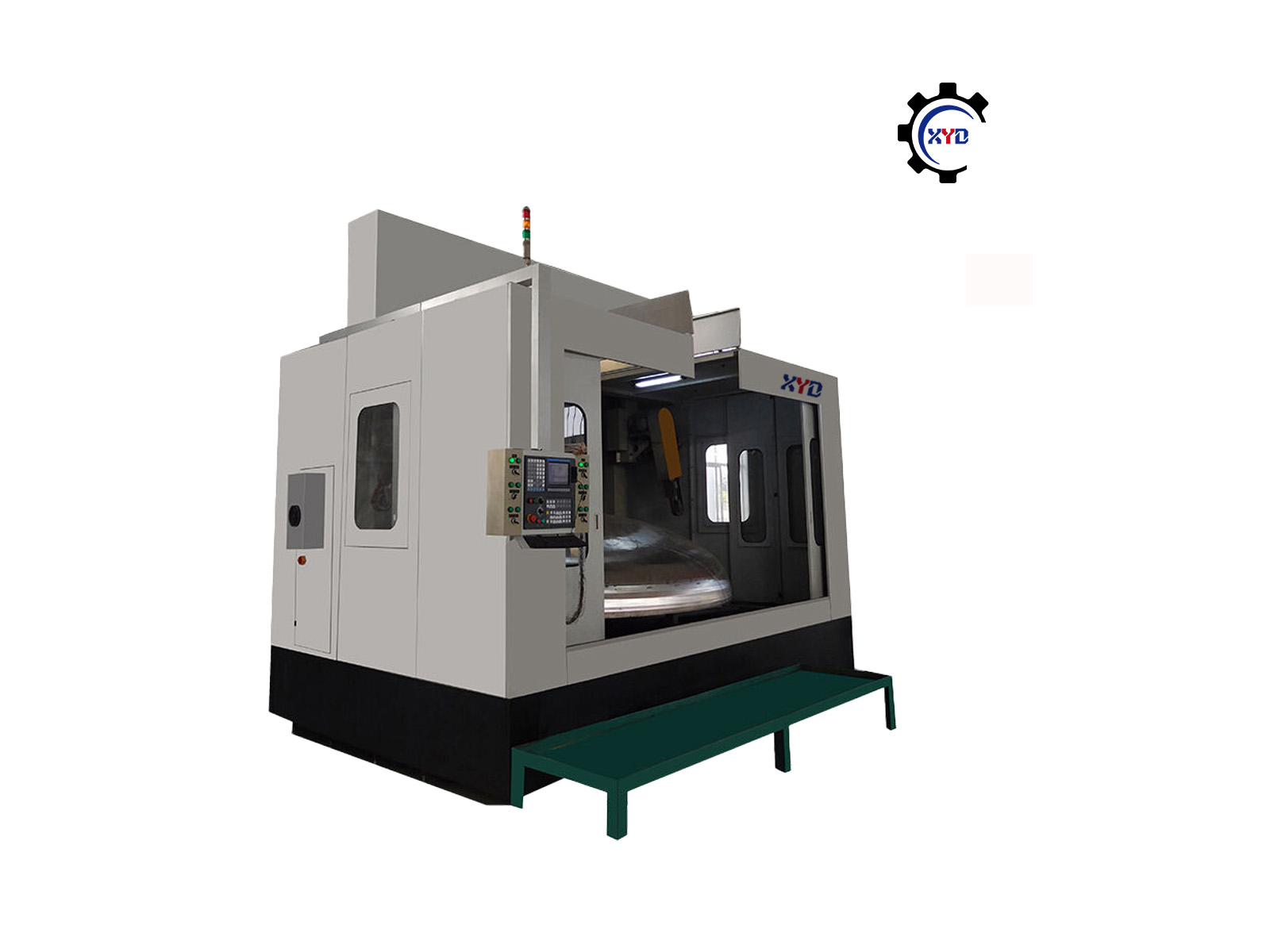

State-of-the-art CNC Polishing Solutions for Complex Shapes

Obtaining a exquisite sheen on intricate units can be a tough task. Traditional polishing methods often struggle to create consistent results on complex configurations, resulting in time-consuming iterations. However, the advent of programmed CNC polishing solutions has upgraded the industry, empowering manufacturers to achieve unprecedented levels of accuracy and efficiency.

These high-tech systems employ computer-controlled machining technology to rigorously polish surfaces with minimal operator intervention. Equipped with precision spindles and a variety of polishing tools, CNC machines can quickly handle even the most demanding profiles.

Moreover, these solutions offer advanced control over criteria such as pressure, speed, and tool path, guaranteeing consistent results across different materials and complexities.

- Merits of automated CNC polishing include:

- Boosted precision and surface quality

- Cut cycle times and production costs

- Elevated product consistency and repeatability

- Increased design flexibility for complex shapes

Rugged Tank Polishing Machine for Industrial Applications

For demanding industrial settings where functionality is critical, a high-torque tank polishing machine is an vital tool. These machines are specifically developed to handle the stresses of repeated operation in severe environments. Equipped with durable construction and high-torque motors, they can effectively clear rust, paint, and different contaminants from tank surfaces, maintaining a smooth and sanitary finish. A variety of tools are available to accommodate different tank sizes and patterns, making them versatile for a wide range of applications.

Adaptive Control-Equipped Dished End Polisher

Our high-tech Dished End Polisher utilizes responsive Adaptive Control Technology to deliver unparalleled accuracy. This tool continuously analyzes the polishing process in real time, maintaining optimal surface grade for a wide range of elements. The Adaptive Control Technology facilitates the adjustment of key settings, such as pressure, speed, and oscillation, to achieve stable results every time.

- Perks include:

- Improved surface finish quality

- Lessened polishing time

- Heightened control over the polishing process

- Adjustability for a range of materials and applications

Computerized Polishing Unit for Superior Surface Treatment

A CNC polishing gadget is a powerful tool leveraged in various domains for generating exceptional surface finishes. These machines use computer numerical control (CNC) technology to systematically polish surfaces, removing imperfections and generating a smooth, refined appearance. The sturdy design of CNC polishing machines supports for high-volume production.

- Production lines

- Non-metals

- Achieving desired textures

The computer-controlled nature of CNC polishing machines maintains steady results, diminishing human error and optimizing efficiency. By utilizing a variety of abrasive materials, these machines can process a large variety of surface forms and ingredients.

Cylindrical Polishing Equipment for Large Diameter Workpieces

Manufacturing and polishing large diameter cylindrical parts often demands specialized equipment. These machines are built to meet precise accuracy levels on objects with significant girth, leveraging a variety of buffing agents.

The choice of cylindrical polishing equipment is contingent upon the specific use case and desired outcome. Some common types include rotary polishers, each offering distinct advantages for perfecting finishes.

- Positioning tools are essential to securely hold large diameter pieces throughout the treatment process.

- Regulating polishing speed and force are critical for delivering consistent results.

Lightning-Fast Dished End Polishing Machine for Mass Production

In present-day speedily developing manufacturing environment, the demand for advanced high-volume production procedures is indispensable. To address this goal, manufacturers are turning cutting-edge technologies like high-speed dished end polishing machines. These next-generation equipment deliver exceptional correctness in a time-sensitive manner, providing consistent quality and superior surface finishes for a inclusive range of components.

Created to handle large production runs with outstanding speed, these machines use advanced polishing techniques to achieve perfect finish required for demanding applications. Fundamental features include high-speed spindles, intelligent control systems, and innovative finishing pads that work in synergy to maximize performance.

As well, these machines often incorporate automation options for increased throughput and reduced labor costs. This combination of speed, accuracy, and machine control makes high-speed dished end polishing machines a vital asset for manufacturers endeavoring to refine their production processes and address the growing needs of the market.

Definitive CNC Polishing for Flight and Medical Devices

In the complex fields of aerospace and medical device creation, surface quality is indispensable. CNC polishing delivers a highly careful and consistent method to achieve the exacting looks required for these critical applications. By utilizing advanced CNC machining technology, manufacturers can create surfaces with exceptional sheen, correctness, and longevity. This process facilitates the production of components that observe stringent requirements for performance, reliability, and soundness.

- needs expectations requirements expectations requirements

- In addition, CNC polishing strengthens the degradation resistance and biocompatibility of items used in aerospace and medical devices.

- Thus, it plays a vital role in extending the lifespan and enhancing the productivity of these products.

Flexible Cylindrical Polishing System for Customization

Revealing a revolutionary method to cylindrical polishing: the Modular Cylindrical Polishing System. This state-of-the-art system allows unparalleled customization, modifying to your specific preferences. With its interchangeable design, you can smoothly adjust the polishing heads, items, and parameters to obtain the intended finish for your cylindrical objects.

- conditions tube polishing machine specifications expectations

- Asset1

- Advantage2

- Gain3